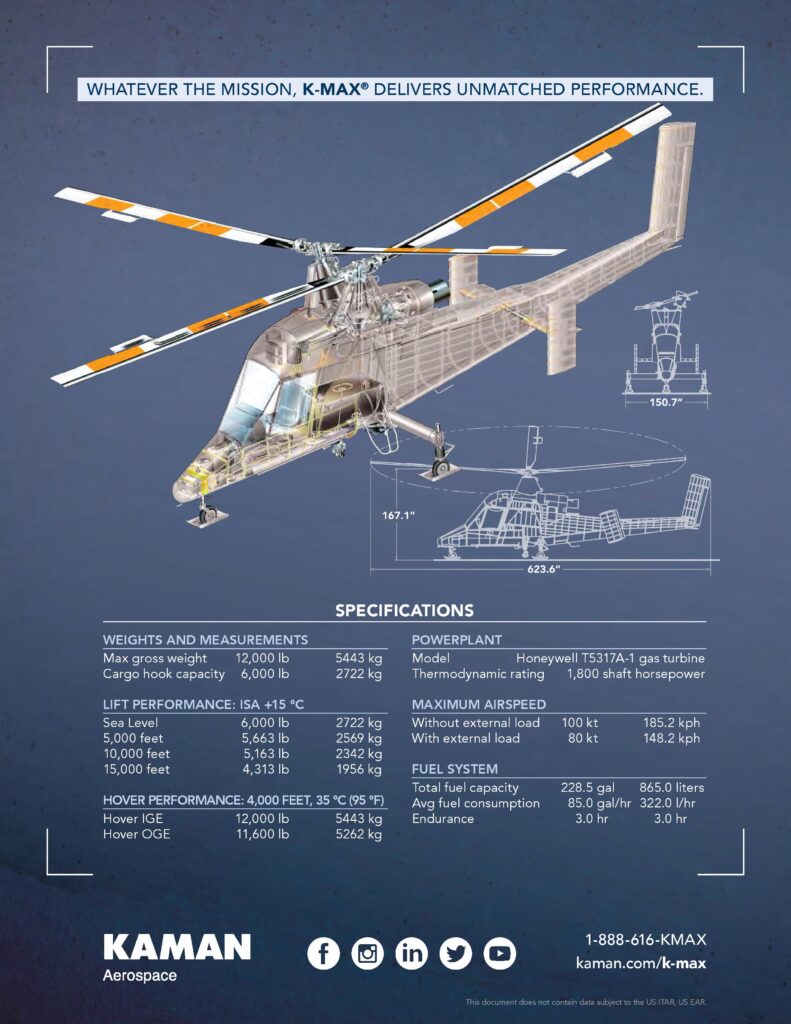

SPECIFICATIONS

APPLICATIONS

Firefigthing

From the US to Europe to Asia to Australia, the K-MAX helicopter is a superb tool in the fight against forest fires due to its ability to carry a significant quantity of water to the fire in hot and high environments. Utilizing a Bambi Bucket® to carry water, the K-MAX can refill the bucket at smaller sources of water that are closer to the fire, thereby putting more water on a fire, quicker.

Military and Defence

With a very successful deployment of the Unmanned K-MAX to Afghanistan with the US Marine Corps, this proven system is an asset to any force. Whether it’s taking supplies and equipment to forward locations, or bringing retrograde loads back to the main base, the Unmanned K-MAX can be a life saver by reducing the amount of ground convoys. And, the addition of additional sensor technologies make it a truly multi-purpose platform.

Logging

The K-MAX helicopter started its commercial life in 1994 as a logging helicopter, and it remains a cost effective means to transport logs from the forest to the log landing. Its payload, and performance at altitude, make it an ideal platform for this very demanding operating environment.

Power Line Construction

Power line projects are some of the most diverse and demanding projects for a helicopter. From carrying concrete for the foundations, erecting the towers, and finally stringing the power lines, all in austere environments, the rugged K-MAX helicopter is ideally suited for the tasks.

Disaster Relief

When there is a crisis and people need help, and transportation on the ground is impeded, the K-MAX helicopter is ready to deliver the equipment and supplies to those who are cut off from the rest of the population. With a payload of 6,000 pounds at sea level, the K-MAX can quickly and accurately deliver supplies to those most in need.

Ski Lift

Similar to power line projects in complexity – moving concrete for the foundations, erecting the towers, and finally stringing the lines – and doing all of this at higher altitudes, the intermeshing rotors of the K-MAX helicopter provide the necessary lift.

Emergency Response

The K-MAX was designed to perform under the most extreme conditions and circumstances, maintaining full capabilities in hot temperatures and at high altitudes. This provides a measurable performance advantage for operators conducting rescue missions or dropping water on fires in mountanous areas.

Heavy-lift capabilities make the K-MAX ideal for disaster relief, as well. It is capable of working long hours while performing repeated lift operations, such as delivering supplies to areas devastated by floods, removing debris from earthquake-ravaged regions, or rescuing individuals trapped on top of a high rise building.

DESIGN

Simple, Safe, and Reliable

The K-MAX can lift more than its weight–6,000 pounds–and burns just 82 gallons of fuel per hour during lift operations, making it the most efficient lift-to-fuel ratio of any helicopter in its class.

The simple, straight-forward design that uses fewer aircraft systems, shortens the load path between the engine and rotor system, enhancing the airframe’s ability to handle the stress loads generated between the rotor system and cargo hook assembly during repeated lifting exercises.

The key to the K-MAX helicopter’s efficiency is an oversized intermeshing rotor system with servo-flap control. Operating without a tail rotor, all engine power is transferred directly to the large counter-rotating main rotors. What’s more, the K-MAX maintains its power and performance at high altitudes and temperatures and requires less maintenance than helicopters with the traditional tail rotor configuration.

Cargo Hook and Trolley

The trolley system allows the cargo hook to move back and forth across the belly of the aircraft, enhancing load stability. The curved track in which the cargo hook rides is part of the heavily reinforced structure that delivers repeated and reliable lifting.

Vertical Reference Design and Innovation

An external instrument panel, strategically located outside of the cockpit of the aircraft, enables pilots to actively monitor performance during load operations. Additionally, the K-MAX operates with a minimum number of systems that require pilot action or monitoring. This means that the pilot can perform all normal and emergency procedures without removing hands or feet from controls.

The aluminum fuselage ranges in thickness from 0.065 inches to 0.125 inches for enhanced durability and safety, especially in critical areas such as the cockpit, fuel tank, and lower fuselage.